Staying up to date and current with collision repair is important. It allows your shop and your techs to deliver the safe, skilled and precise repairs. With new procedures, new materials and new standards being set by OEM’s, it is possible to miss the latest requirements. This could lead to faulty, improper repairs if the wrong procedure is used on the wrong material.

Not all materials are created equal and Honda is on a mission to let us know. Honda now uses ultra-high-strength steel in their vehicles, specifically in the door ring in the A & B pillars, roof and sill side stiffeners. Ultra-high-strength steel (UHSS) is defined as any steel with a tensile strength of 980 MPa or higher.

The UHSS used in Honda vehicles is rated up 1,500 MPa grade steel.

It is light and very strong, but heat sensitive and must be replaced as a single unit. This steel cannot be sectioned or straightened during repairs. Honda released a case study showing the importance of collision repair done right. Honda used two 2014 Acura MDX’s and subjected them to a small-overlap crash test (video below). One of the MDX’s was from the factory floor and the other was ‘repaired’ using unauthorized OEM repair techniques by Honda.

The factory floor model MDX held up in the crash test.

The incorrectly repaired MDX’s door buckled and cause damage that led to more structural damage due to incorrect repair practices. The door also buckled during the crash test on the incorrectly repaired MDX which would trap the driver inside. The factory floor MDX door was openable and held up to Honda’s safety standards.

With safety being the number priority, Honda wants repairs done right. When it comes to their 1,500 MPa ultra-high-strength steel, Honda calls for replacement. Honda says, “Do not apply heat to any body part during straightening.

This may compromise the internal structure and strength of high-strength steel parts. Any part that has heat applied to it during straightening must be replaced with new parts.” That also means that MAG welding is out. According to Honda, MAG welding must never be used on 1,500 MPa steel because the heat generated by MAG welding significantly reduces the strength and integrity of the steel.

Honda requires that UHSS replacement parts must only be joined at factory seams by squeeze-type resistant spot welding. If the spot welder cannot reach the repair location, Honda suggests using MIG brazing.

These welding methods will not warp, weaken or compromise the ultra-high-strength steel and comply with Honda OEM UHSS repair requirements.

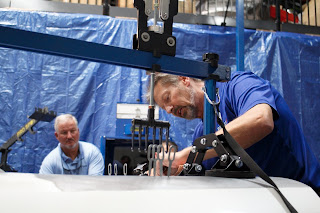

There are specific spot welder requirements needed for Honda OEM repairs just as there are specific repair procedures. A high-strength spot welder capable of exceeding 772 lbf clamping pressure and

producing more than 9,000 AMPS is required for Honda certified OEM repairs. Pro Spot offers a range of spot welders, such as the i5 and i4, that meet Honda’s requirement for spot welders capable of UHSS repair. Pro Spot also has a high-pressure gun and arms available either at the time of purchase or to retrofit existing units with.

MIG Brazing is a low heat, MIG welding method that uses adhesion instead of fusion to join metals.

MIG Brazing is a low heat, MIG welding method that uses adhesion instead of fusion to join metals. This method is required by Honda when a spot welder cannot access a part of the vehicle that needs repair. The requirements for a Honda approved MIG welder include: a pulse mode, an input voltage of 220V and 180 AMP minimum output. Pro Spot offers the SP-5.3, SP-5, SP-2 and SP-1

all of which meet the Honda welding equipment repair requirements. All of these pulsed MIG/MAG welders can be paired with the high-strength welding wire, required by Honda, to complete MIG brazing repairs.

Find all the Pro Spot, Honda approved

spot welders and MIG brazing MIG/MAG welders here.

In case you need a visual example, here is what happens when collision repair is done wrong. Incorrect repair procedures can not only lead to structural damage but can also throw off the timing on an air bag. Watch and find out what a mistimed airbag does to a watermelon.

Ouch.

Sources for images, videos and information:

ProFirst Collision VideoUse Your Melon Video2016 HR-V: New Model Body Repair Information

Pro Spot International, manufacturers of resistance spot welding equipment for the collision repair industry, announces the recent Tesla approval of the SP Series MIG Welders including the SP-5 Smart MIG and the new SP-5.3 3-Phase Smart MIG. The welders are approved for aluminum welding during structural repairs on Model S and Model X.

Pro Spot International, manufacturers of resistance spot welding equipment for the collision repair industry, announces the recent Tesla approval of the SP Series MIG Welders including the SP-5 Smart MIG and the new SP-5.3 3-Phase Smart MIG. The welders are approved for aluminum welding during structural repairs on Model S and Model X.  The Tesla approval joins many others of the SP MIG Welders including Mercedes-Benz, Jaguar, Land Rover, Honda/Acura, Ford’s F-150, the Cadillac CT6, Corvette and more. The SP Series MIG Welders are unique in many ways but they stand out for their ease of use and the 3 dedicated torches to Aluminum, Silicon Bronze and Steel. For details on the specific OEM programs and approvals, contact Pro Spot.

The Tesla approval joins many others of the SP MIG Welders including Mercedes-Benz, Jaguar, Land Rover, Honda/Acura, Ford’s F-150, the Cadillac CT6, Corvette and more. The SP Series MIG Welders are unique in many ways but they stand out for their ease of use and the 3 dedicated torches to Aluminum, Silicon Bronze and Steel. For details on the specific OEM programs and approvals, contact Pro Spot.